Photo Credits: Hindustan Times

Cricket Ball: The product you know; The story you do not

- By Ayush Nanda-- Copyeditor Jazreen Deboo--

- February 02, 2022

Cricket Ball, Unorganized Sector, Meerut, Sports Goods, Cottage Industry, Wages

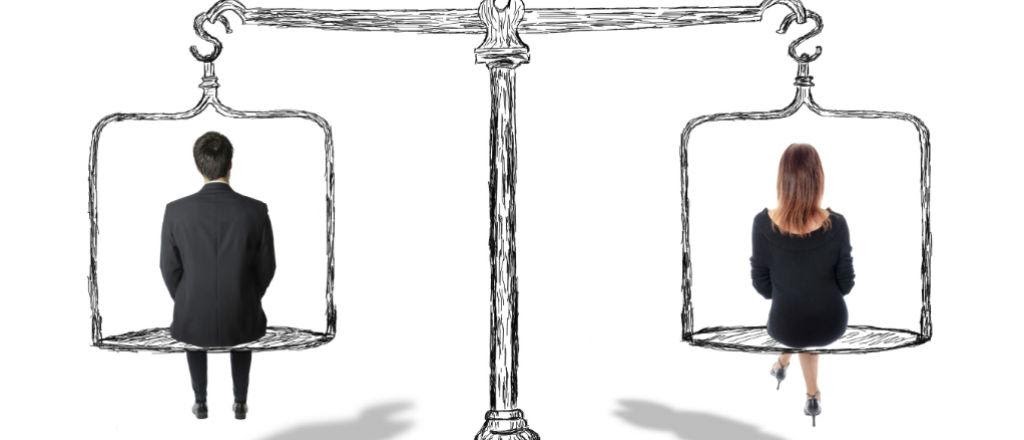

For a cricket ball of second-grade quality, whose market value is around INR 300-500, the one who stitches the ball receives just INR 20-30. This exploitation and the unfair distribution of profits is observed not only in the cricket ball sector but is prevalent throughout the sports goods industry.

Cricket is not just a sport but an emotion in India, and if you have played the game, you have probably come across a cricket ball made in Meerut. Meerut is the sports goods hub of India; here, more than 10,000 people in 30 villages are involved in manufacturing cricket balls.

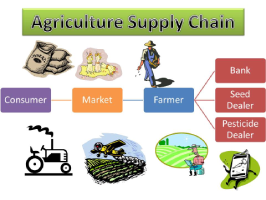

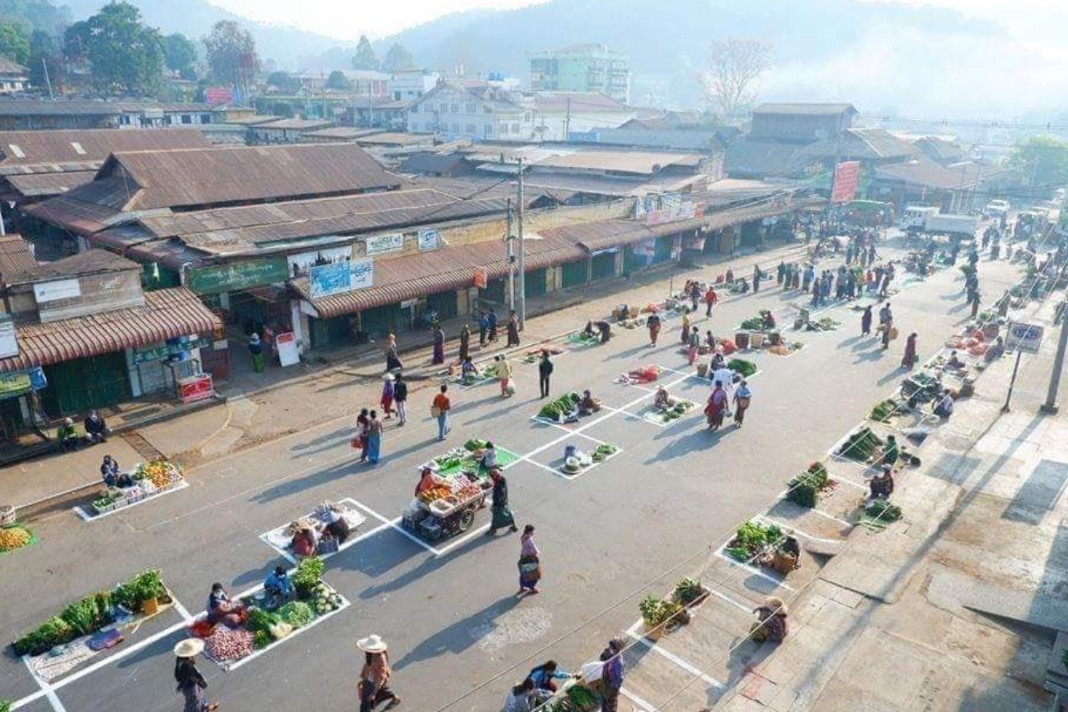

Sports goods manufacturing is highly unorganized in Meerut. One can find thousands of home-based ball units run by small families, with the support of one or two employees. The same is true for cricket ball manufacturing. These cottage industries work as an integral part of the overall supply chain of the industry. This article provides an interesting backstory into the production of an Indian cricket ball, its unique selling points, and, more importantly, the people behind its creation.

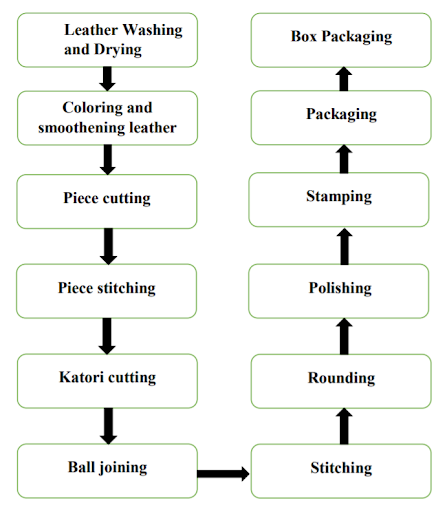

The specialty of the cricket balls produced in Meerut is that the product is entirely hand-stitched, compared to its machine-stitched competitor in export markets, the Australian Kookaburra ball. The pronounced seam offers more spin and bounce and is better suited for Indian conditions. Cricket ball manufacturing is a complex process, including ten key steps. The ball-making skills are transferred from one generation to the next through the “ustaad system”.

Fig 1: Process of Manufacturing Cricket Balls

The most important raw material is leather, and the final price of a ball depends on leather quality. The highest quality of the leather is locally known as “puttha leather”. The leather and other raw materials are provided to home-based workers, who create the finished or semi-finished product and are inadequately compensated for the same.

The market value of a second-grade quality ball is INR 300-500, while an SG Test Cricket match ball costs around INR 1500-2000. The workers in Meerut are paid INR 20-30 per ball for their efforts. According to the All-India Sports Goods Manufacturing Federation, 60% of the sports goods manufactured in India are exported, out of which 45% are produced in Meerut. The intermediaries and sports giants pocket high profits. At the same time, the actual makers' labour costs and working conditions remain poor.

This exploitation and the unfair distribution of profits is observed not only in the cricket ball sector but is prevalent throughout the sports goods industry. On interacting with women workers, we found that they are compensated INR 1.50 for their efforts of stringing one badminton racket and INR 30 for sewing an entire football.

“The reason why this exploitation continues is that so many people from Meerut are engaged in sports good manufacturing that there is no dearth of cheap labour,” said an official of the district. “So, a few people protesting against low wages would only be replaced by others willing to work for less. Also, the market of Meerut is already saturated and there is high competition among dealers. A new enterprise would have to find buyers outside the district, which can be challenging initially.”

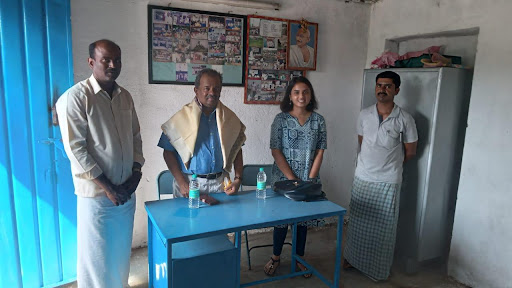

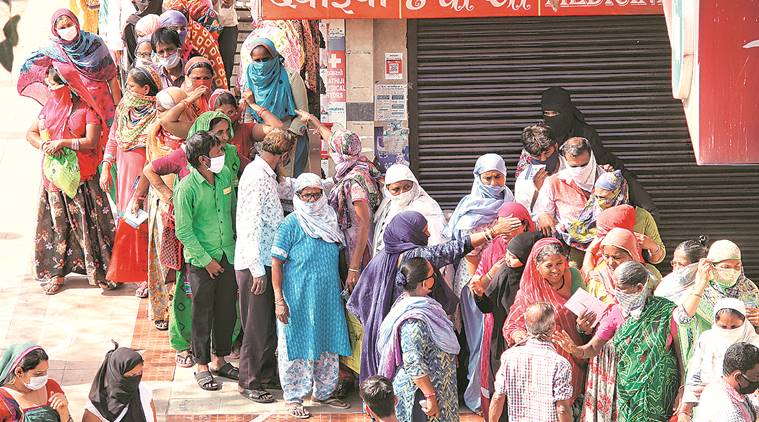

Figure 2: MGNF Ayush Nanda and SRA Paritosh Pathak of IIM Bangalore visiting home-based cricket ball units in Meerut.

Scope for Intervention

The production of cricket balls in India is about 180,000 dozen per year, valued at more than INR 300 lakhs. The demand for quality goods is increasing, hence there is a scope for another 10 to 15 new units every year. The manufacturing process requires highly skilled labour with specific expertise, which is why the industry has been able to survive the onslaught of highly mechanized methods used abroad.

According to the Ministry of Commerce, the value of sports goods manufactured from Meerut in 2017-18 was Rs 1,079 crore.

As an intervention to remedy the current situation, the Mahatma Gandhi National Fellow, along with the National Rural Livelihood Mission (NRLM) staff of Meerut, is working to consolidate the individual efforts of these women and give it a shape of a village enterprise.

(1) A cricket ball unit entirely run by women of Self-Help Groups would be established. After identifying women who are already engaged in ball-making, forward and backward linkages would be established.

(2) These women will be trained under the One District One Product Scheme of the Uttar Pradesh Government and will also be provided with a work kit free of charge.

(3) For setting up a manufacturing unit, credit would be provided to them through the credit linkage scheme of NRLM. This can be replicated with other SHGs of Meerut manufacturing different products if successful.

(4) In the longer run, the idea is to establish an umbrella organization that will market village-level enterprises' products under one common brand, hence solving the problem of marketing and inequitable profit distribution.

The skills are already there; we need to formalize the labour and organize them into functional groups to pursue micro-entrepreneurship.

MGNF Ayush Nanda, with support from the District Skill Committee, has submitted a proposal for the setting up of a cricket ball manufacturing unit, mobilized women from five villages and persuaded three Self Help Groups to apply for the registration of the firm. Currently, the loan process is underway.

Reference

[1]. Sgmea.org. 2022. SGMEA | Sports Goods Industry of India.

http://sgmea.org/sports_goods_industry_of_india [Accessed 4 January 2020].

[2]. Duttagupta, I., 2018. Meerut's sports goods industry turns its focus on athletics to other niche areas. [online] The Economic Times. Available at: https://economictimes.indiatimes.com/industry/miscellaneous/meeruts-sports [Accessed 6 January 2022]

Ayush Nanda